Fast etch rates and low clean overheads mean higher tool uptime. Higher uptime means more wafers through your fab

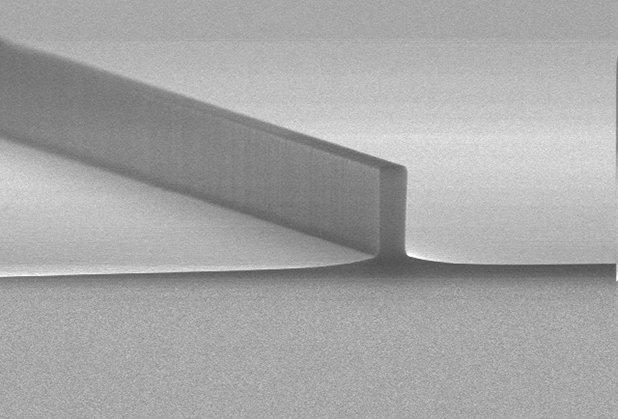

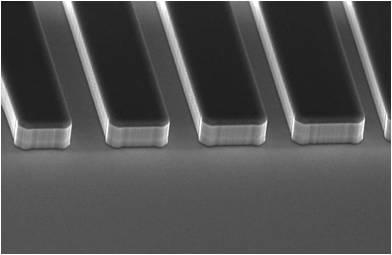

Vertical facets means higher device efficiency – more light out for power in

Smooth surfaces means less light scattering – more usable light

Essential with such complex structures, stopping in the right layer can make or break your device

Uniform etch depth means that more devices can be made from each wafer, improved yield decreases costs