PTIQは、Plasma Technology社製プロセスシステム用の最新スマート ソフトウェア ソリューションです。パワフルなスケジュール機能と優れたレポートツールにより、抜群のシステム制御を実現し、プロセス効率の向上とワークフローの新たな可能性を切り開きます。また、PTIQソフトウェアは、ラボとファブにおけるシステムとプロセスのパフォーマンスを最適化し、施設の要件に合わせてさまざまなレベルのソフトウェアを利用できます。

注:現在、PTIQソフトウェアに不具合が発生していますが、非常に特殊なレシピ編集に限定されているため、通常はこの問題に悩まされることはありません。この問題をデバッグするために、こちらをクリックしてください。

PTIQソフトウェアのデモをウェビナーで視聴

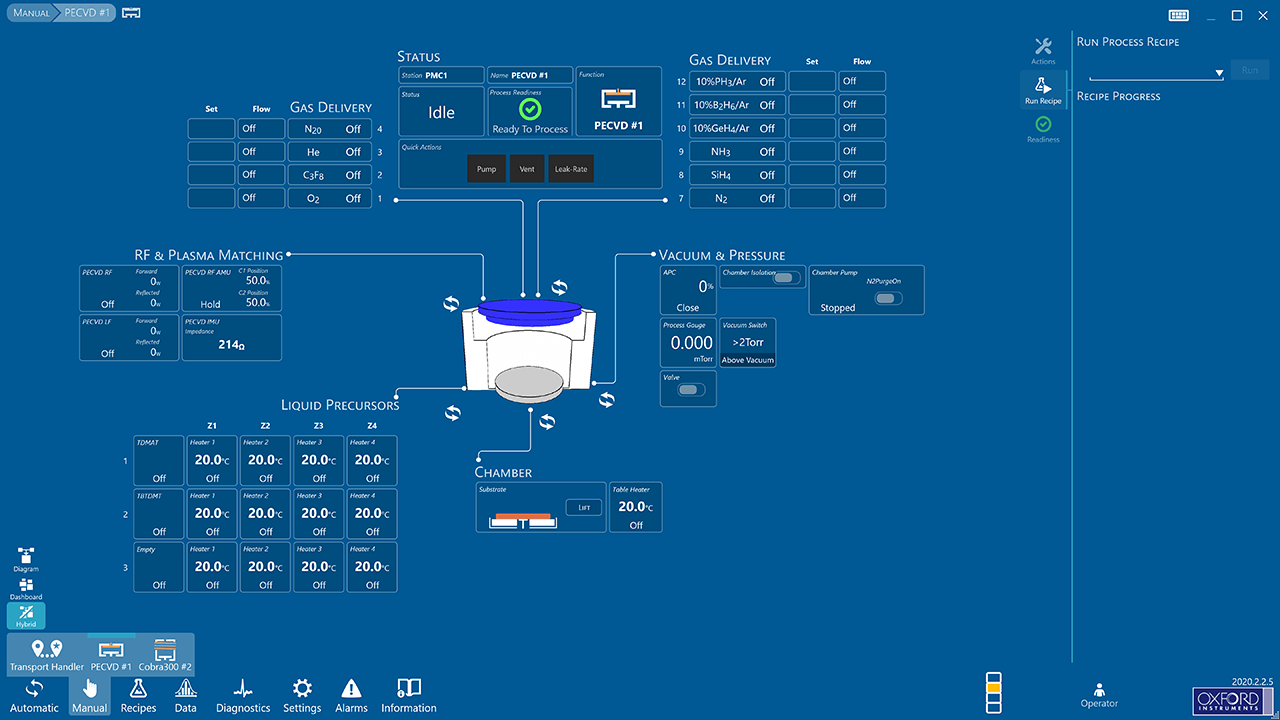

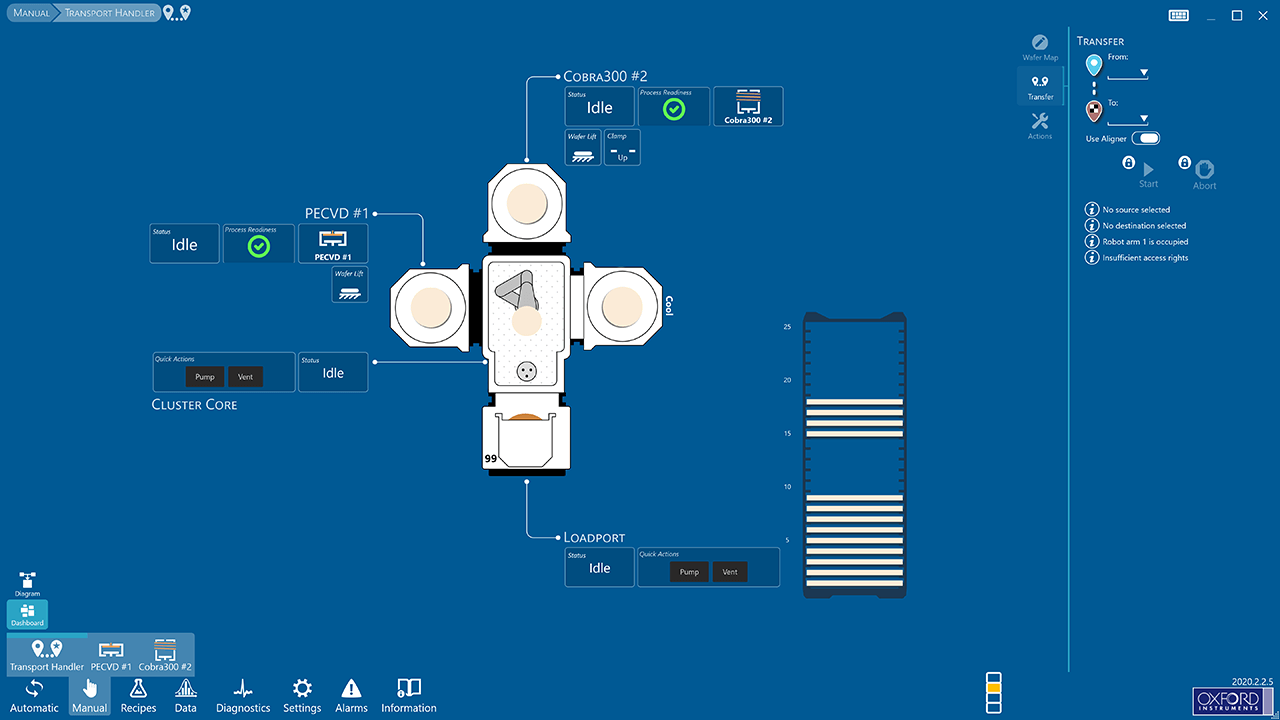

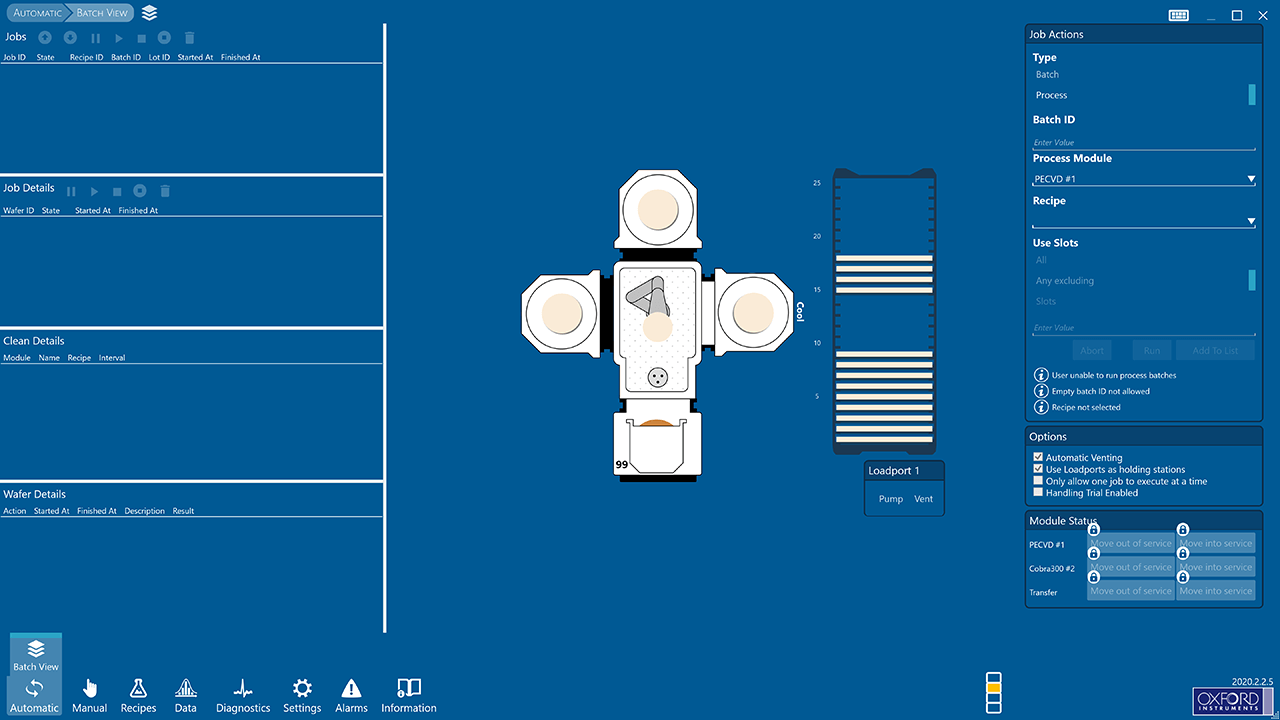

PTIQ 画面レイアウト

自動化された半導体工場で使用するために、SECS/GEMリンクを介してオックスフォードの機器を工場のホストコントローラに接続するソフトウェアモジュールです。

PTIQ AnalytIQsは、システムの稼働時間を最大化するための分析ツールセットで、データの統計分析を通じてプロセスログデータをより深く理解し解釈することができます。PTIQ LogViewerをさらに拡張し、すべてのシステムパラメーターの追跡と分析を可能にします。

カタログダウンロードプロセス中に取得したデータを測定、分析、報告するための上位モジュールです。

セルフメンテナンス システムやトラブルシューティングに不可欠なエンジニア向け解析ツールセットにより、機器を制御する電子機器の中枢部まで掘り下げることができます。これらは、オックスフォード・インストゥルメンツのカスタマーサポートエンジニアが利用できるツールと同じものです。

このプレミアムモジュールは、レシピ、設定、プロセス実行データをリモートコンピュータに定期的にバックアップする役割を担っています。

これは、アーカイブのため、または必要に応じて外部処理のためにデータを転送するために使用されます。

現在PC2000またはPC4500をお使いのお客様が、PTIQにアップグレードする場合にも、いくつかのアップグレードパスが用意されています。アップグレードが完了すると、自動的にオックスフォード・インストゥルメンツのソフトウェア保証契約に登録されます。

また、サイト全体のPTIQアップグレードプランもございますので、サイト全体を割引料金でアップグレードし、今後のソフトウェアサポートの継続性を確保することができます。

PTIQコントロールソフトウェアに不具合が確認されておりますので、ご報告いたします。この問題は、2021.13.02までのPTIQのすべてのバージョンに該当します。この問題は、非常に特殊なレシピ編集(レシピステップ内でサブステップを使用する)に限定されているため、通常はこの問題に悩まされることはありません。この問題をデバッグするために、こちらをご覧ください。

当社は新しいソフトウェアに大変な自信を持っており、実際に動作しているところをご覧いただきたいと思っています。ライブデモのウェビナーがオンデマンドで視聴できるようになりました。

PTIQのメリットとその効果についてご確認いただくことができます。