Diamond offers a set of characteristics that make it an interesting choice for a wide range of applications. It has the highest known thermal conductivity making it attractive for heat removal, is chemically un-reactive and is the hardest known material. It also has a wide (5.5eV) indirect bandgap meaning it has a high breakdown voltage. It can be etched using Inductively Coupled Plasma (ICP), Reactive Ion Etching (RIE) or Ion Beam Etch (IBE).

- As a substrate for high power devices it is robust, lightweight and able to transfer heat from the active region better than any other material whilst tolerating high applied voltages.

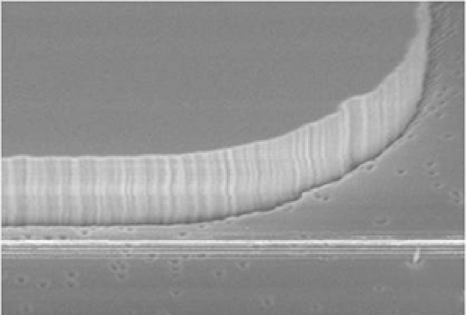

- It is a suitable replacement for silicon in MEMS devices where wear and bio-compatibility are a concern and can be combined with piezo-electric materials like AlN to form high frequency SAW devices. Its optical absorption is low across the visible spectrum, which combined with a high refractive index allows it to be used for applications like waveguiding.

- The leading candidate for quantum information processing, where NV centres can be interrogated to give information about the quantum states.