PTIQ is the latest intelligent software solution for PlasmaPro, Atomfab and Plasmalab processing equipment. PTIQ provides an exceptional level of system control as standard, as well as the option for extra performance with PTIQ Pro.

Offering an exceptional level of reliability and repeatability, PTIQ will optimise system and process performance in the Lab or Fab, with different levels of software available to suit facility requirements.

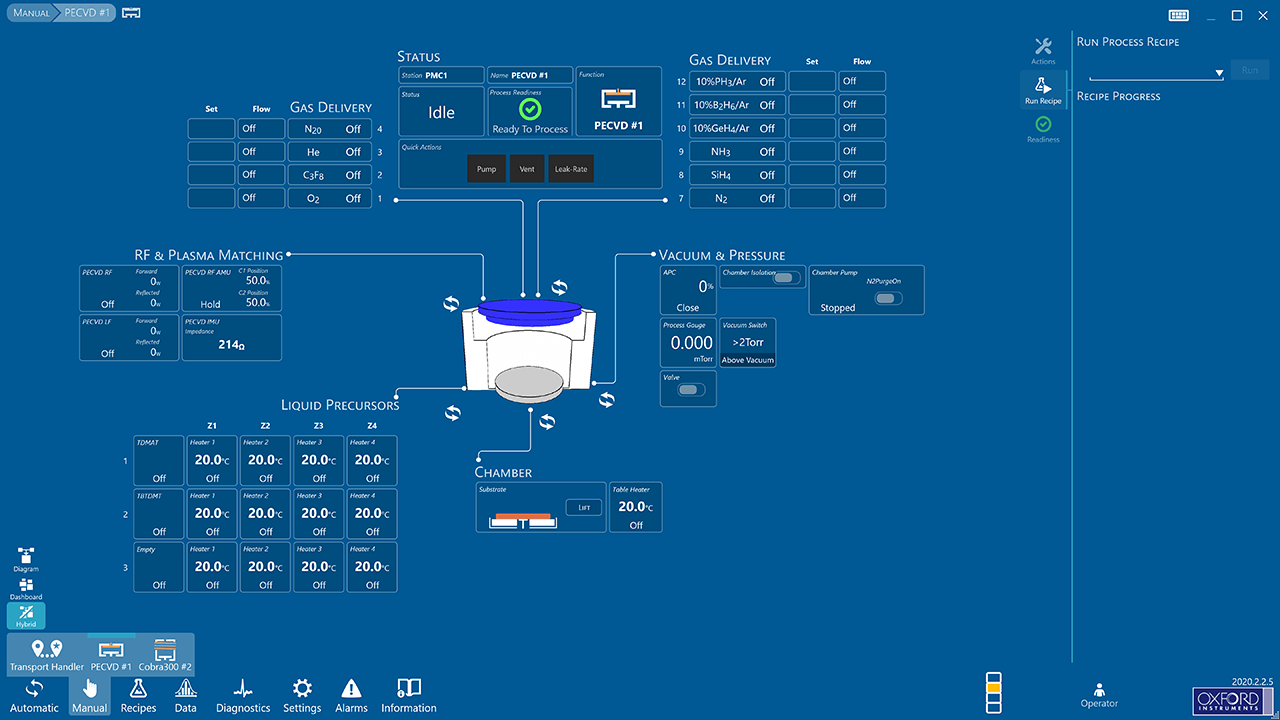

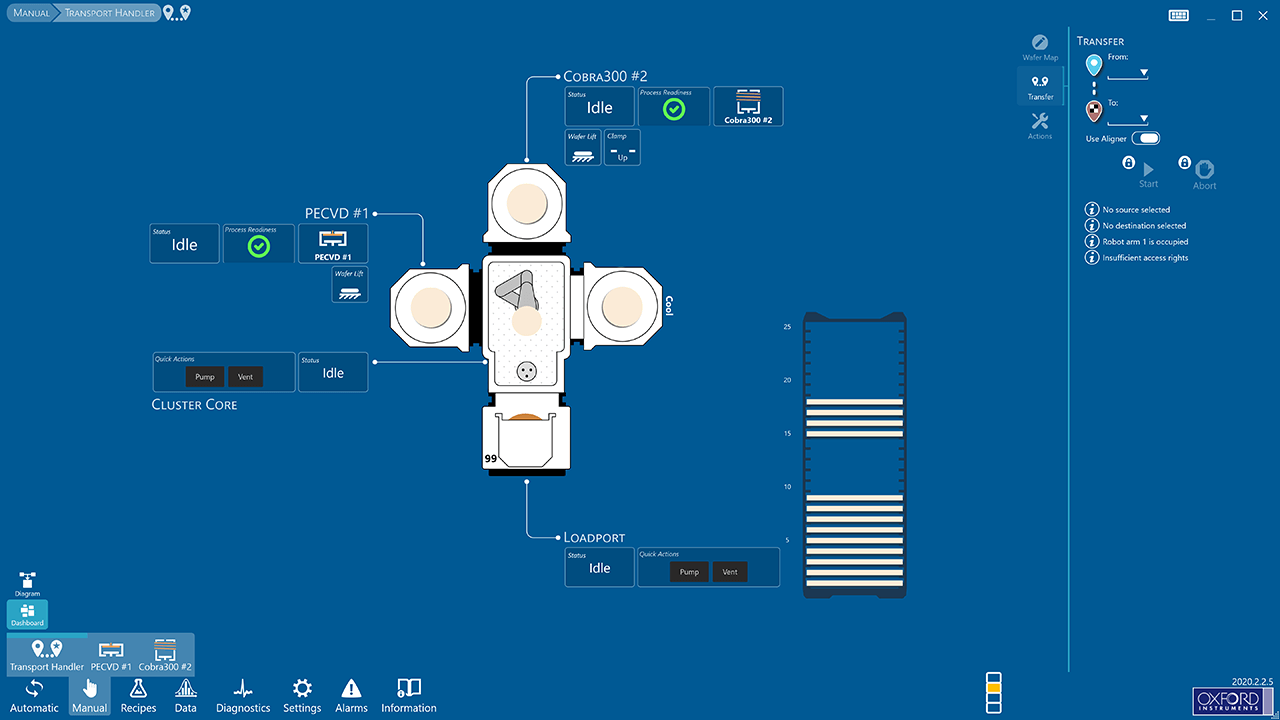

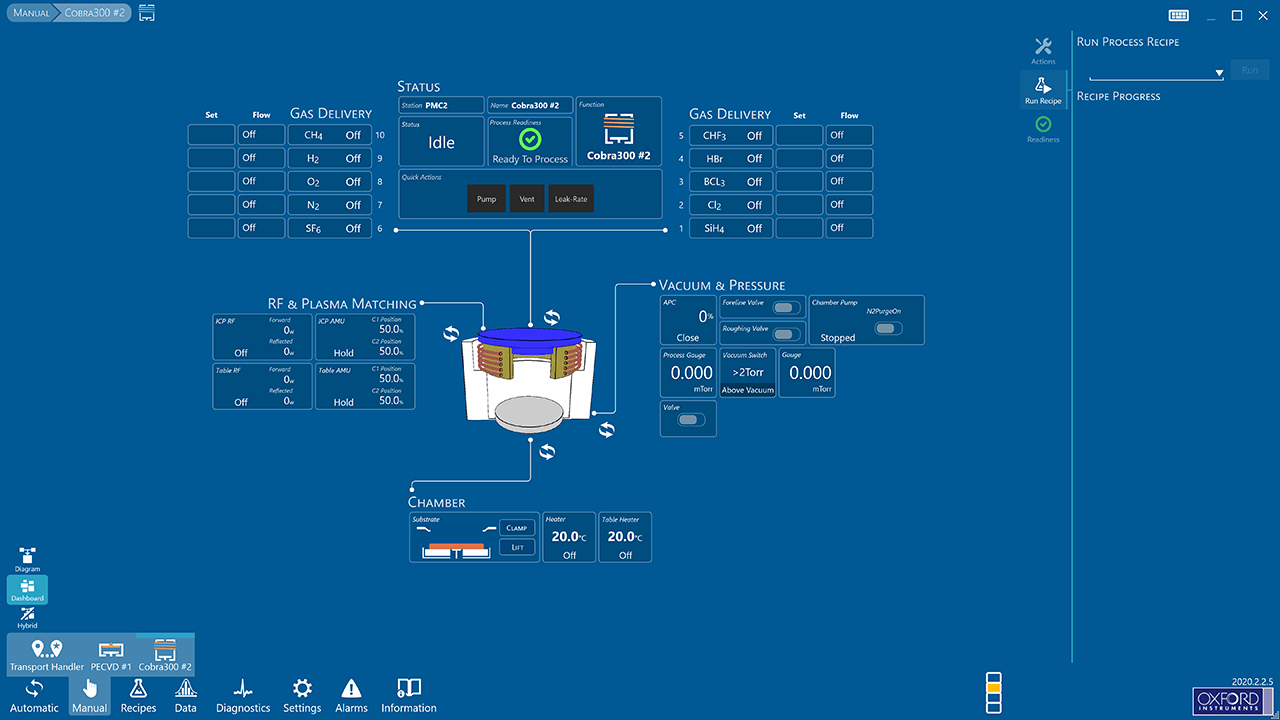

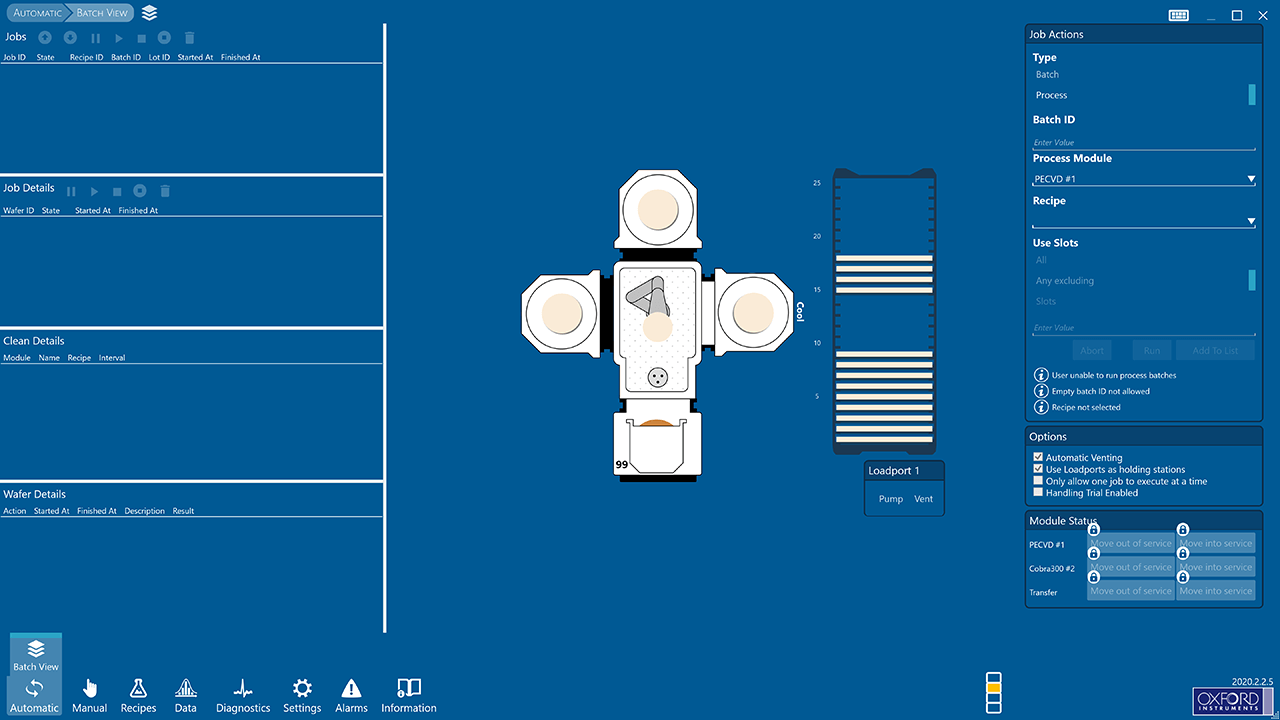

PTIQ Screen Layout

If you currently run a system with PC2000 or PC4500, and want to upgrade to PTIQ, we have several upgrade paths available.

We also have site-wide PTIQ Upgrade plans; you can upgrade your whole site for a discounted rate to ensure continuity of software support going forward.

*PTIQ upgrade is not currently available on FlexAL or Ionfab platforms.

**System upgrade eligibility will be assessed on a case by case basis, however you can use the eligibility checker here to make a start.

DOWNLOAD BROCHUREWhen is this available?

PTIQ is available now.

Since February 2020, systems have been quoted, are being built, and leaving the factory with PTIQ. At present, around 75% of our product line is utilising PTIQ, meaning PlasmaPro 100, 80, and 800 are currently set up for the new software. Our new ATOMFAB system also includes PTIQ.

Before the end of the year, it will be made available on our Ionfab, Estrelas and Polaris systems.

What are the hardware upgrades that we need to have to be able to upgrade to PTIQ?

This will be evaluated case-by-case, but there are some minimum specifications we need for PTIQ to work on an existing set of hardware:

If I have an etch system and a deposition system, will it be the same software and work the same way?

Yes. This was an important goal for the new software to give a consistent look and feel and to find the common actions needed to operate all our systems.

There will be a few notable differences, but they relate to the specific technologies involved. This means that, whether the modules exist on the same cluster configuration or are side by side as two separate single module tools, the software will be the exact same.

Does this work with cluster systems?

We support our three families of products with PTIQ: open-load, single module and out cluster systems. All three types of system have the same look and feel and operate in a similar manner.

Is PTIQ touch screen compatible?

We have designed the software with the view that it will be controlled via a touchscreen, ensuring that with a 24” touchscreen that the active areas will be at least 1cm square. Although the SEMI E95 standard is no longer active, it does still serve a purpose in helping to make a touchscreen operator interface for Semiconductor Capital Equipment.

Is PTIQ multi-monitor compatible?

This is on our short-term roadmap. We built the software from the ground up with dual monitor support from the beginning, but this is not yet available to be activated in the software as this feature needs a little more work before it is complete.

With existing PC4500 software, LogViewer log files can be viewed on another PC if manually transferred to another PC. It would useful if remote users could more easily access data files and analyse it. What will the new software offer?

We will soon be packaging the Datalog viewer as a standalone product so that it may be installed on a separate PC. We are looking to make the process of transferring files much easier.

Can a parameter (e.g. RF) be graded from start and end value through a loop?

This feature is in the process of being developed as we seak to support the more advanced deep silicon etch processes. Our implementation will be available for all process modules when it is released, not only the Estrelas tool.

Do you have a simulator of this software that we can install in our personal computer for testing or training?

We have a simulator/emulator that can be used for this purpose. For example, it does a very good job of emulating the hardware including some simple algorithms to emulate the physics involved in pressure control.